På Materialise World Summit 2017 – Think. Beyond. Together. i Bryssel var Co-creation och innovation temat under två fullspäckade dagar som inleddes med föredrag av bland andra Materialise CEO Fried Vancraen och Belgiens vise statsminister Alexander De Croo. Konferensen bestod av två spår, Health Care och Additive Manufacturing, jag deltog i den senare.

Det som slog mig var att företag nu börjat titta på affärsmodeller kopplat till additiv tillverkning (AT) – bland annat Siemens, SAP och Catia visade alla sina nya affärssystem – hur man enkelt från ett CAD-program med några få klick kan få sin detalj utskriven av en leverantör och hemskickad. På AT-konferenser brukar presentatörerna mest tala om delar som skrivits ut med hjälp av AT eller hur man använder sig av AT. På denna konferens handlade temat/diskussionerna däremot om samarbetade och hur flera olika partners gått ihop för att skapa mervärde, alla exempel var naturligtvis från Materialises samarbete med olika kunder.

Titel på Andreas Saar, VP Manufacturing Engineering Solutions, Siemens, föredrag var “Additive manufacturing reshapes everything. Reimagine products. Retool manufacturing. Rethink business”. Saar påpekade att de fyra största värdena han såg var: Individualization, Product Optimization, Manufacturing Efficiency samt Business Models, men han gav även exempel på begränsningar som till exempel Disconnected Software, Multiple File Conversions, Uncontrolled Workflow och Conventional Thinking.

Hoya Vision Care talade om transformativ innovation – glasögon har alltid köpts utifrån vald båge sedan har man beställt glas till dessa men deras vision är att börja utifrån glaset med en mer approach som utgår från kundbehovet. ”What if… we could create the ideal spectacles by putting the lenses in the optimal position and ensure the best visual performance? Based on… prescription, functional needs, previous experience, ergonomics – not on frame.” Något de nu kan göra med sin 3D-skrivna kollektion. Fördelarna Hoya såg var att när en glasögondesign blivit godkänd så kunde bågarna finnas tillgängliga i 3000 butiker inom 24 timmar.

Mohammad Ehteshami, Vice President, Additive Integration, GE Additive, USA (bilden) talade om självlärande skrivare och han svarade JA på frågan om GE skulle lansera en egen skrivare efter köpet av Concept Laser och Arcam. Han ville däremot inte gå in på detaljer och på frågan om hur stora utskrifter man skulle kunna göra i metall i framtiden så svarade han METER, så det ska bli intressant att följa dem.

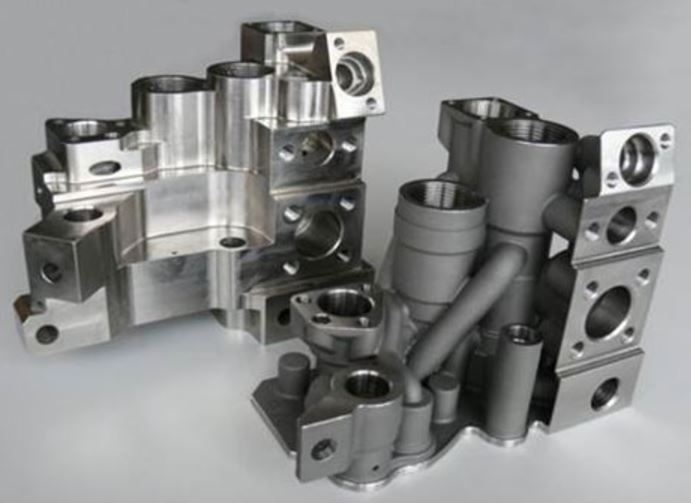

Mest imponerad blev jag av DB, det tyska järnvägsbolaget, där Uwe Fresenborg, CEO, DB Vehicle Maintenance GmbH, berättade om deras satsning på 3D-skrivna reservdelar. 2016 skrev de ut 1000 stycken, 2017 blir det 4000 detaljer och 2018 är prognosen 15.000 stycken. Delarna sitter i tågen och spårväxlar etc. och han var väldigt nöjd över resultaten både i fråga om kostnad och om de tidsbesparingar som gjorts, utöver hållbarheten i delarna.

//Mi Åberg